Contractors

Resources/Blog

FAQ's

Press

About Us

Contact

Contractors

Resources/Blog

FAQ's

Press

About Us

Contact

Gutter machines are excellent investments for general contractors, roofing specialists, and companies in various other trades. Learning all you can about gutter machines, including care, maintenance, and even transportation, can have a positive impact on your companys overall profitability by creating a significant return on your investment. Below, you can read about the best ways to choose (and care for) the right gutter machine, tools, accessories, and materials to ensure that your new investment works like new for many, many years to come.

The first thing you should consider before you purchase a gutter machine is the gutter sizes and profiles you are most likely to install for your clients. Typically, you will find gutter machines in 5, 6, 7, and 8 inch sizes, and you can even find 5"/6" and 6"/7" combination machines, along with 6 inch Half Round. Most contractors will benefit the most from 5/6 combo gutter machines as they offer the most versatility with multiple turnstiles, but there are some exceptions. If you work in an area where rainfall is scarce or where rainfall rates are typically low you may not need to produce anything above 5. On the other hand, if you work in an area where torrential rainfall is common, or if you have numerous industrial clients, a 7 machine may benefit you.

Gutter machines also allow you to make gutters in different profiles, and the most common include half-round, K-style, and fascia gutter profiles. Each of these offers up its own unique set of benefits for home and business owners in your local area, so be sure that you find out which gutter styles is most common among your clientele. When you decide which sizes you will provide in your area, be sure that you purchase the materials and accessories recommended for those particular sizes.

Gutter machines are investments, especially for smaller contractors and roofing companies, so it is important that you have all the best information available if you really want to utilize your gutter machine to help your company grow. Some of the best ways to do just that include:

If theres one thing that home and business owners appreciate more than anything else, its the ability to get multiple projects done quickly and affordably. Thats exactly what a gutter machine will allow you to do. Rather than having to scour the local area for gutters, call multiple companies, and wait a long time for someone to install their new gutters, you can do the job for them. This saves your clients time, money, and trouble, which is always a good thing. Similarly, you can offer your clients more gutter product options like gutter guards to add even more value to them.

Whether your company already installs gutters or youre considering the idea of adding it as a service, you will save money over time by buying the raw materials rather than buying finished gutters. In fact, with a bulk discount and a gutter machine, you can generate significant revenue by adding gutter installation to your services list. Also you will save time not waiting on your supplier to drop off your gutters at the jobsite.

The more services you can offer, and the more affordably you can offer them versus your competition, the better your reputation will be over time. After all, people are more likely to recommend professionals who do quick, great work for an excellent and competitive price.

Like other types of machinery, numerous companies manufacture gutter machines and accessories, and each one of these companies is different in its own way. Two of the most popular manufacturers are:

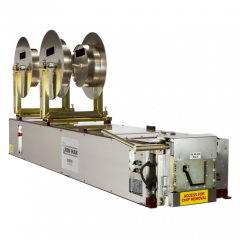

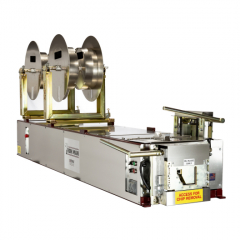

KWM Gutterman, manufacturers of the Ironman gutter machines are the most popular in the industry, and they come in a wide variety of sizes, profiles, and types. They offer useful features like transfer bars for easy coil loading. Whether you need 5, 6, 7, 8 or a combination of these or even a next-generation smart gutter machine KWM Gutterman offers it all.

Another manufacturer of gutter machines, New Tech Machinery, offers a 7 commercial box gutter machine. This machine is recommended for commercial use and comes loaded with standard features and can be customized to fit your unique business needs.

Each of these companies will also allow you to build your own gutter machine from various parts and accessories. If you need something very specific, this may be the best choice.

Before you decide based on size, profile, and manufacturer alone, there are a few other important considerations. Size and style are important, but you should also consider the drive roll material, shipping and delivery options, accessory options, and whether the machine is new or used.

The two most common options are polyurethane drive and steel drive, and polyurethane is by far the better option in almost every case. They are far lighter, they create less material waste, and they are free-floating, so you dont have to have the machine loaded with coil from one project to the next. You can also create gutters with 24-gauge steel with polyurethane, and this is simply not an option with a steel drive roll. Just keep in mind that the polyurethane options will cost more upfront.

Gutter machines are heavy and quite large, which can present some unique challenges for shipment and delivery. Typical lead time for standard machines (5", 6", 5/6" combo machines) is 2-4 weeks to ship out. Any other machines will be determined by current lead time. Many purchases qualify for free shipping. Machines must be delivered to a commercial address with a loading dock and forklift. Please call a sales representative to check lead time, before purchasing to get accurate current lead times.

The accessories available for your gutter machine depend on the manufacturer as well as the machine size and style. Some of the things you will need to run your machine efficiently include upright and spools or cradles and a guillotine, and in some cases, these come along with the gutter machine as a bundled package. However, you may need to buy them separately. Other options include things like run-out stands as well as riser pads, transfer bars and floor mount cradles.

Last, you may be tempted to buy your first gutter machine used if you want to save money, but this is typically best reserved for those who are familiar with them. These machines must remain perfectly aligned (adjusted) to operate correctly, and older machines tend to be a bit more finicky in this regard. Also, a used machine typically wont include a warranty which is definitely recommended for an expensive item like a gutter machine.

If you choose to add a second gutter machine later down the line after youve familiarized yourself with adjusting them, a used machine is an option. However, used machines come with greater risk that you can't always see until you do a couple of gutter run outs.

Like any other investment, you will need to make sure that you take the time to maintain your gutter machine in order to keep it up and running like new for as long as possible. After all, the more use you can get from your new machine, the more profit you can generate. Here are some tips for maintaining your gutter machine to extend its useful life and avoid major repairs.

These are by far the most important things you can do to keep your gutter machine looking and running like new. Read all warning labels on machine. Perform a daily inspection for debris, loose nuts and/or bolts. Lubricating the Guillotine blade with 30 weight oil daily. The gears don't need to greased, and the bearings inside most gutter machines are sealed and self-lubricating, so they require no additional lubrication. Always keep covers and lids on machine during transportation, operation and storage. The covers are for the operators safety. Not only will the covers protect the operator against injury, but they will protect the machine from outside elements. Disconnect the machine from the power source prior to cleaning or performing any maintenance.

Looking over your machine now and then will help you spot any potential problems early on, which can save you a great deal of money in terms of repairs. If you find any loose or bare wires or connections, stop using your machine until you can get these repaired.

You should never leave a gutter machine out in the open where it can be subject to rain, snow, and other precipitation. Invest in a gutter machine cover at the very least, or better still, keep it inside in a climate-controlled environment.

Outdoor storage: This is not recommended, but if machine must be stored outside, tarp the machine loosely in order to provide sufficient ventilation to prevent condensation.

After your gutter machine arrives, you will need to find the best way to transport it from one jobsite to the next. It is crucial that you do everything you can to reduce the effect of typical movement and shock that comes from transporting your machine. This includes ensuring that the entire machine is secure, and performing a thorough inspection after each trip. Most companies tend to use box trucks to move their gutter machines as they provide an enclosed, safe environment that will help to extend their lives. It is also possible to utilize an enclosed trailer, though these tend to create a great deal of vibration. If you purchase an enclosed trailer its highly recommended to get barn style doors and not ramp style doors. Do not transport or store machine with gutter coil in it. The forming rollers have adequate spacing, which will not allow them to come in contact with one another. The polyurethane drive rollers do not need to be protected from each other. Use a 5,000 watt minimum generator if you decide to use that as a power source.

Open trailers are not ideal, though they can be used to transport your machine relatively short distances on smooth pavement. When utilizing the latter method, be sure to use a gutter cover that has been properly secured to prevent any dust or debris from getting inside the various parts of the machine.

Your gutter machine may or may not come with the various other tools and equipment you need to operate it safely and efficiently. Some of the most common accessories include:

Cradles fit behind your gutter machine where the material enters and holds your gutter coil. This is an absolute must for making gutter machines simpler and safer to operate. The two options for cradles are floor mount and machine mount cradles. Please buy machine mount cradles only from the manufacturer of that machine.

A gutter machine cover is an important investment. It fits over the machine to prevent dust, dirt, debris, rain, snowfall, and more from getting into the machine itself where it can cause serious issues. Though a gutter machine cover should never take the place of proper storage, it is a great option for temporary protection while on a jobsite.

Run-out stands are designed to hold the gutter in place as it exits the machine to prevent any bending or bowing. You should use one stand for every 15 feet of metal at the very least, though many companies prefer to use one stand for every 10 or 12 feet.

A guillotine may or may not be included with your gutter machine purchase. Its purpose is to cut the gutters to length as they exit the machine. It is beneficial because it creates a much cleaner cut than hand trimming, and it is also much quicker, which improves productivity.

Coil spools are another must-have. Spools are inserted into the gutter coil, then locked in place then are placed into the uprights. Spools also protect your gutter material by ensuring a proper feed, which allows you to produce perfect gutters every time.

Your gutter machine is only profitable when you have a wide selection of material for your clientele to choose from. Depending on where in the country or world you work, gutter material popularity will vary a great deal. Some of the most popular options and the ones you should always keep in stock include:

Across the US, aluminum is by and large the most popular gutter material for many different reasons. They are available at a very low cost to homeowners and they have an average life expectancy of 30 years. Aluminum comes in a variety of colors, as well as mill finish. These machines will run .027 or .032 thick aluminum.

Whereas aluminum is one of the most affordable gutter materials on the market, copper is one of the most durable. It is commonly used in historic renovations and on large homes with a very luxurious aesthetic appeal. Copper lasts for generations, and while it may look like a brand-new penny for a short while after installation, it will gradually develop the green patina that is popular and loved by many. It is not only attractive, but it is also highly beneficial. As the sulfate builds on the copper due to oxygen exposure, the thicker it becomes, the more it protects the metal from corrosion. It is this patina that makes copper gutters last for centuries. These machines will work with 16 ounce and 20 ounce material.

Galvalume is an aluminum- and zinc-coated steel product that allows home and business owners to reap all the benefits associated with all three of the metals. Galvalume has the strength and durability of steel with the corrosion and rust resistance of both aluminum and zinc. The steel is hot-dipped in a coating consisting of 45% zinc and 55% aluminum. The material has a bit of architectural sheen, and as it weathers, it does so more evenly than other materials. It has been tested in every imaginable environment and climate since 1975 and remains a favorite today. These machines will work with 26 and 24 gauge material.

Galvanized steel differs from Galvalume in that there is no aluminum used in the process; sheets of steel are hot-dipped in zinc which provides them with unsurpassed corrosion resistance. The zinc creates a barrier between the steel, which is strong but known for its susceptibility to corrosion and rust, and the air and moisture in the outdoor environment. The result is a longer-lasting and more aesthetically pleasing steel gutter system that is perfect for homes, businesses, and industrial centers. These machines will work with 26 and 24 gauge material.

Last, but most certainly not least, be sure that you have a plan in place for adjusting your gutter machine as necessary. Gutter machines are wonderful pieces of equipment and can provide you with a significant return on your investment, but they can only do this when they create beautiful, functional gutters without any problems due to alignment or adjustment issues. As such, consider the three following options.

The manufacturers of gutter machines understand that there is a learning curve when it comes to adjustments. As such, many of these manufacturers have complete courses in various places across the country where professionals and experts will teach you how to make those adjustments on your own. Before you go this route, keep in mind that you will need to pay for the travel costs and the course, and you will also need to be able to set aside time as necessary to adjust the machine.

Some contractors have benefited significantly from sending one or two of their employees to take the course, then come back and train the other employees including the company owners. If you have employees who are mechanically-inclined (or who have a degree in a mechanics field) and who you can trust, this may be the best course of action. The more people onsite who know how to make the adjustments correctly, the better.

If your company is still quite small, but growing, you may choose to hire an expert in your local area to make the adjustments as needed. Adjusting your machine is a part of its routine maintenance, so if you go this route, you may want to consider hiring someone to clean, lubricate, and adjust your machine all at the same time.

For the latter option, gutter machine experts sometimes travel across the country providing service to various contractors, and while this may be more convenient for you when it comes to regular maintenance and adjustment, it can be problematic if you need an adjustment right away but you dont know how to do it. As you can see, it is important to weigh your choices carefully.

If you have been thinking of purchasing a gutter machine, or if you have already purchased one and youre curious about the best way to turn a profit, these tips can certainly help. To sum up, choose a machine that produces the gutters your target demographic prefers in terms of size, style, and material; maintain, transport, and store your machine as per the manufacturers guidelines; and have a plan in place for making any necessary adjustments both during maintenance and on the fly.

Check out our other product offerings to stay stocked up on essential gutter supplies like gutter downspouts and hangers.